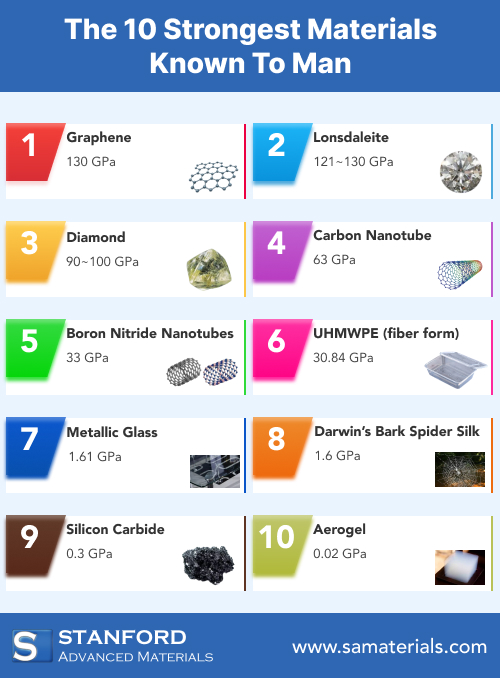

The 10 Strongest Materials Known To Man

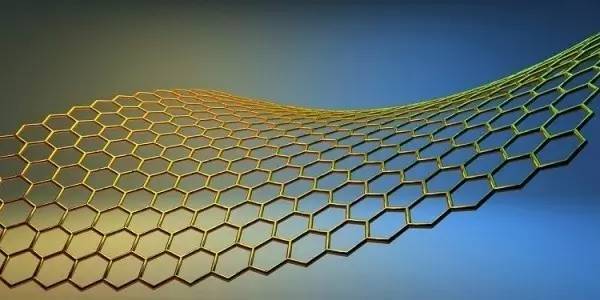

1. Graphene (130 GPa)

Graphene is the strongest known material, with unmatched tensile strength due to its single-atom-thick carbon lattice.

Graphene is a honeycomb two-dimensional film formed by carbon atoms with sp2 hybridization. It is a monolayer sheet structure separated from graphite, and it is also the thinnest new material currently known. The tensile strength and elastic modulus of graphene are 130 Gpa and 1.1 tpa, respectively, and its strength is 100 times that of ordinary steel. Bags made of graphene, which can hold about 2 tons of weight, are by far the strongest material known.

2. Lonsdaleite (121~130 GPa)

Lonsdaleite, a rare hexagonal form of diamond, is theoretically stronger than conventional diamond.

The Lonsdale stone was discovered in a crater by American geologist Lonsdale and defined as a hexagonal meteorite diamond. Like diamonds, they are made of carbon atoms, but their carbon atoms are arranged in different shapes. The results of the simulation show that the Lonsdale stone is 58% more resistant to pressure than the diamond.

3. Diamond (90~100 GPa)

Diamond features exceptional tensile strength and hardness thanks to its compact tetrahedral crystal structure.

Diamond is the hardest substance found on earth in so many natural forms, and it is an allotrope of carbon. The hardness of diamond is the highest level of Mohs hardness - grade 10. Its microhardness is 10000kg/mm2, which is 1,000 times higher than quartz and 150 times higher than corundum.

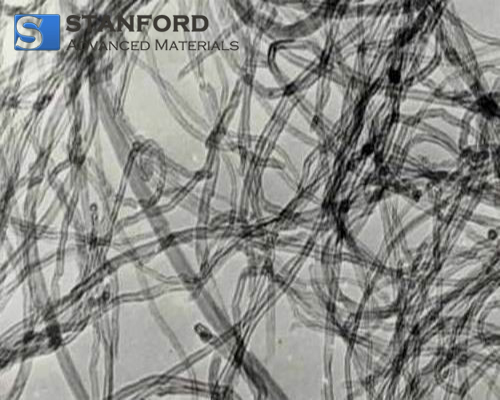

4. Carbon Nanotube (63 GPa)

Carbon nanotubes combine extreme strength and light weight, making them ideal for structural nanomaterials.

Carbon nanotubes (CNTS) are a kind of one-dimensional quantum material with the hexagonal arrangement of carbon atoms forming coaxial circular tubes from several layers to dozens of layers, and it can be divided into single-walled carbon nanotubes (SWCNT) and multi-walled carbon nanotubes (MWCNTs) according to the number of layers of graphene sheets. Carbon nanotubes have excellent mechanical properties. Besides, its elastic modulus can reach up to 1TPa, which is equivalent to that of diamond and about 5 times that of steel.

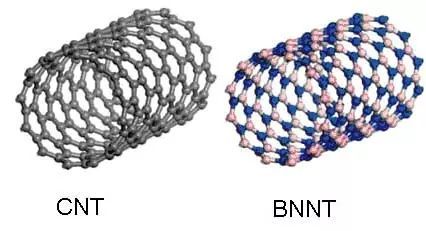

5. Boron Nitride Nanotubes (33 GPa)

BNNTs are structurally similar to carbon nanotubes but offer better thermal and chemical stability with comparable strength.

Like carbon, boron nitride can form single-atom sheets that can be curled up to form nanotubes. The boron nitride nanotubes themselves are as strong as carbon nanotubes, but the real advantage comes from their ability to stick firmly to the polymer as it binds to the polymer. The strength of boron nitride nanotubes is higher than that of carbon nanotubes, about 30% higher than PMMA interface, and about 20% higher than epoxy resin.

Boron nitride nanotubes have optical properties, excellent mechanical and thermal conductivity properties, as well as withstand high temperatures and absorb neutron radiation, thus becoming effective additives for mechanical or thermal enhancement of polymer, ceramic and metal composites. Additional applications of boron nitride nanotubes include protective shields, electrical insulators, and sensors.

6. UHMWPE Fiber (30.84 GPa)

Ultra-high molecular weight polyethylene fiber is used in armor and medical devices due to its high strength-to-weight ratio.

UHMWPE is a kind of fiber made from polyethylene with a relative molecular weight of 1 million to 5 million, which is currently the strongest and lightest fiber in the world. It is 15 times stronger than steel wire but very light in weight, and it is 40 percent lighter at most than materials such as aramid.

7. Metallic Glass (1.61 GPa)

Metallic glass features high strength and elasticity due to its disordered atomic structure.

Metallic glass is also called amorphous metal, which is usually an alloy, with an amorphous structure and glass structure. This double structure determines that it has many properties beyond the reach of crystalline metal and glass, such as good electrical conductivity, high strength, high elasticity, more wear-resistant and corrosion-resistant. Metallic glass is stronger than steel and harder than hard tool steel.

8. Darwin's Bark Spider Silk (1.6 GPa)

This spider silk stands out as one of the toughest biological materials, outperforming most synthetic fibers.

A new species of spider, Darwin's bark spider, has been found on Madagascar to create the world's largest and most solid web. At 25 meters wide, the spider's web is the strongest biological material ever studied and 10 times stronger than kevlar of the same size.

9. Silicon Carbide (0.3 GPa)

Silicon carbide is a durable ceramic known for thermal resistance and moderate tensile strength.

Silicon carbide is a natural mineral in nature, or it is made from quartz sand, petroleum coke (or coal coke), wood chips and other raw materials by smelting at high temperature in a resistive furnace. Silicon carbide is hard with a Mohs hardness of 9.5, which is second only to the world's hardest diamond. In addition, silicon carbide has excellent thermal conductivity. It is a kind of semiconductor and can resist oxidation at high temperature.

![]()

10. Aerogel (0.02 GPa)

Aerogel is an ultralight material with minimal tensile strength, but valuable for thermal insulation.

Aerogel is a form of solid material that has the smallest density in the world. Aerogels are very strong and durable and can withstand pressure thousands of times their mass, and they don't melt until it reaches 1200 degrees Celsius.

Thank you for reading our article. If you want to learn more about the strongest materials, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

References

- Banerjee, A., et al. (2018). Ultralarge elastic deformation of nanoscale diamond. Science, 360(6386), 300–302.

- Chen, X., Dmuchowski, C., Park, C., Fay, C., & Ke, C. (2017). Quantitative Characterization of Structural and Mechanical Properties of Boron Nitride Nanotubes in High Temperature Environments. Scientific Reports, 7.

- Class for Physics of the Royal Swedish Academy of Sciences. (2010, October 5). Scientific Background on the Nobel Prize in Physics 2010: Graphene [PDF]. Nobel Prize. Archived

- Ding, J., Chen, G., Huang, W., Cheng, J., Li, T., Cheng, C., & Xu, J. (2024). Tensile Strength Statistics and Fracture Mechanism of Ultrahigh Molecular Weight Polyethylene Fibers: On the Weibull Distribution. ACS Omega, 9.

- Kazuki Takashima, Akira Ishida. (2008). Metals and Alloys. In Y.B. Gianchandani, O. Tabata, & H. Zappe (Eds.), Comprehensive Microsystems (pp. 53–73). Elsevier.

- Kono, N., Ohtoshi, R., Malay, A. D., Mori, M., Masunaga, H., Yoshida, Y., Nakamura, H., Numata, K., & Arakawa, K. (2021). Darwin's bark spider shares a spidroin repertoire with Caerostris extrusa but achieves extraordinary silk toughness through gene expression. Open Biology, 11(12).

- Li, Q., Yi, S., Li, Z., & Yu, Z. (2011). Lonsdaleite – A material stronger and stiffer than diamond. Scripta Materialia, 65, 229–232.

- Magagnosc, D. J., & Schuster, B. E. (2019). Fracture strength of hot-pressed silicon carbide at the microscale. Materials Science and Engineering: A, 765, 138297.

- Ünal, H., Sert Çok, S., Koç, F., Gizli, N., & Pekbey, Y. (2019). Investigating the effect of silica aerogel content on the mechanical properties of epoxy resin system. Research on Engineering Structures and Materials.

- Yu, M. F., Lourie, O., Dyer, M. J., Moloni, K., Kelly, T. F., & Ruoff, R. S. (2000). Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science, 287(5453), 637–640.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento