What Are the Characteristics of Hexagonal Boron Nitride?

Introduction to hBN

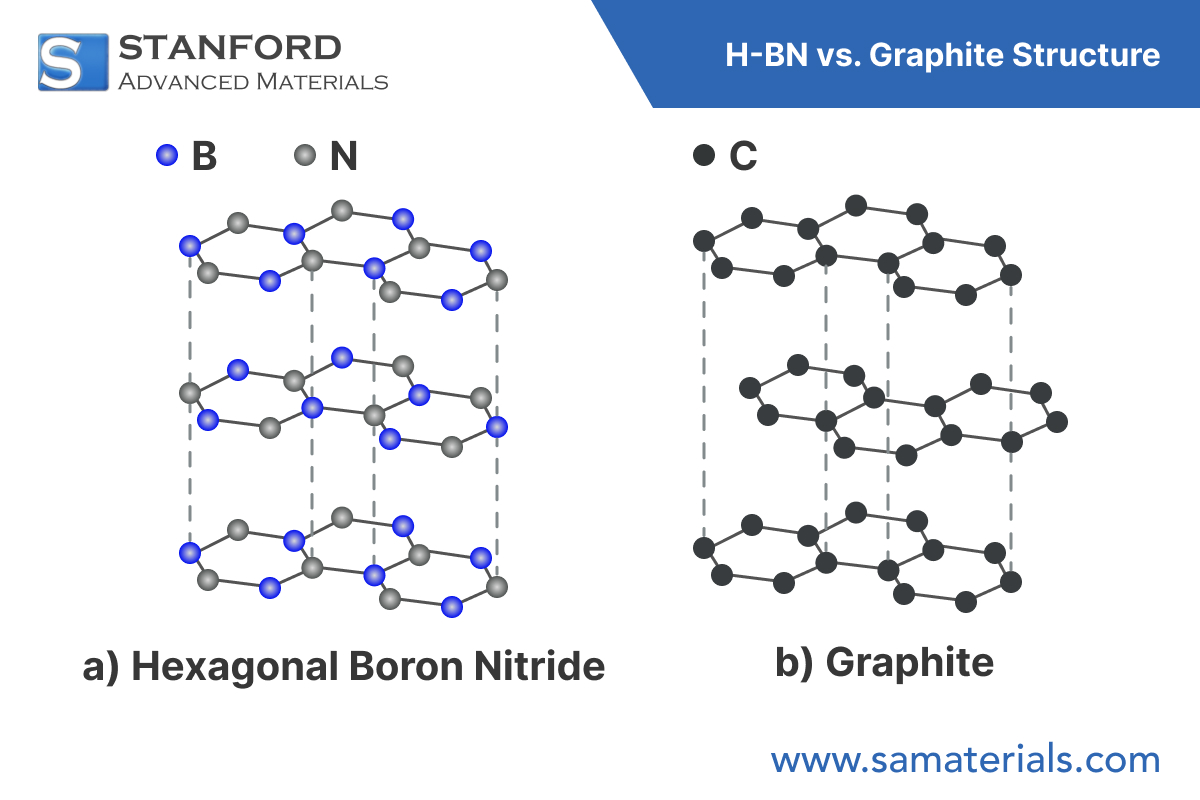

Hexagonal boron nitride (hBN) is an advanced ceramic material with unique thermal, electrical, and chemical properties. Commonly called "white graphite," hBN features nitrogen and boron atoms arranged in hexagonal mesh layers that overlap to form crystals. These crystals exhibit graphite-like structure with diamagnetism and high anisotropy, sharing similar crystal parameters.

Due to its exceptional properties, hBN serves numerous applications including:

- Refractory materials

- Semiconductor solid-phase doping sources

- Atomic stack structural materials

- Neutron radiation shielding packaging

- Rocket engine components

- High-temperature lubricants and mold release agents

Physical and Chemical Properties

Hexagonal boron nitride (white graphite) is a loose, lubricating, moisture-absorbing white powder with a true density of 2.27/cm3, a Mohs hardness of 2, and low mechanical strength, but higher than graphite. It has no obvious melting point and sublimates at 3000℃ in 0.1Mpa nitrogen. Its stability in an oxygen atmosphere is poor, and its use temperature is below 1000°C.

Hexagonal boron nitride has a low expansion coefficient and high thermal conductivity, so it has excellent thermal shock resistance, and it will not be damaged even after hundreds of cycles at 1200-20°C. The expansion coefficient of BN is equivalent to that of quartz, but the thermal conductivity is 10 times that of quartz.

Electrical and Thermal Performance

Hexagonal boron nitride is characterized by a good heat conductor and a typical electrical insulator. Its room temperature resistivity can reach 10^16~10^18. Even at 1000℃, the resistivity is still 104~10^6Ω.cm. The dielectric constant of BN is 3~5, the dielectric loss is (2~8) *10^-4, and the breakdown strength is twice that of Al2O3, reaching 30-40 Kv/mm.

Key Characteristics and Advantages

Hexagonal boron nitride has good lubricity, oxidation resistance, corrosion resistance, insulation, thermal conductivity, and chemical stability. It can be used to manufacture TiB2/BN composite ceramics, high-grade refractory materials and super hard materials, horizontal continuous rolling steel separation rings, high-temperature resistant lubricants, and high-temperature coatings, and also a raw material for the synthesis of cubic boron nitride.

It is characterized by excellent chemical stability, neither wetting nor acting on most metal melts, such as steel, stainless steel, Al, Fe, Ge, Bi, Si, Cu, Sb, Sn, In, Cd, Ni, Zn, etc.

Industrial and High-Tech Applications

Therefore, it can be used as a high-temperature galvanic couple protection cover, melting metal crucible, utensils, pipes for conveying liquid metal, pump parts, cast steel abrasive tools, and high-temperature electrical insulation materials. Due to the heat and corrosion resistance of BN, it can be used to manufacture high-temperature components, rocket combustion chamber linings, heat shields for spacecraft, and corrosion-resistant parts for magnetic flow generators.

Conclusion

Thank you for learning about hexagonal boron nitride's characteristics with us. For more technical information about boron nitride materials, please contact Stanford Advanced Materials (SAM).

As a global hBN supplier with 20+ years of experience, we provide:

-

High-quality hexagonal boron nitride products

-

Custom material solutions

-

Reliable technical support

We're confident SAM can meet your boron nitride requirements for both R&D and production applications. Contact us today to discuss how we can partner on your next project.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento