Wurtzite Boron Nitride (w‑BN): Structure, Properties, and Applications

1. Introduction

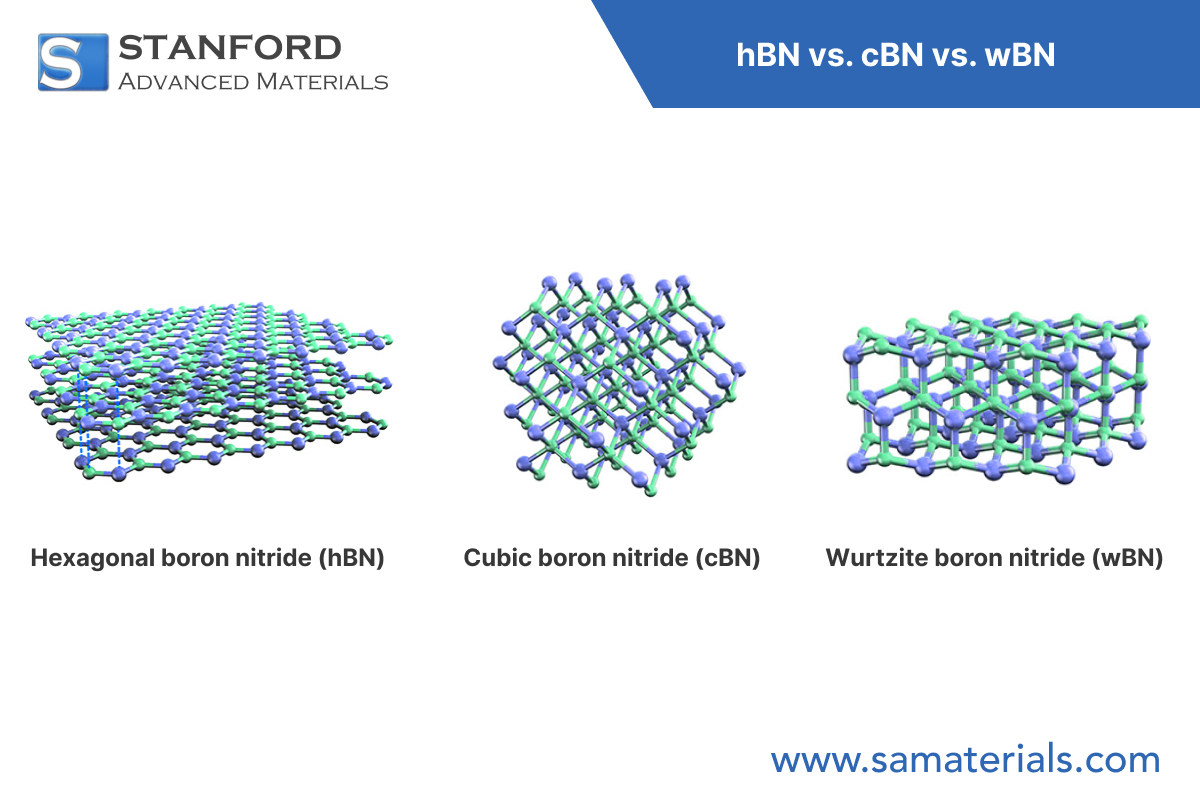

Boron nitride (BN) exists in multiple crystalline forms, with the most studied being hexagonal (h‑BN), cubic (c‑BN), and wurtzite (w‑BN). Among these, w‑BN is the least common but exhibits extraordinary mechanical properties that have attracted increasing attention in high-performance applications. Structurally similar to wurtzite-type materials like GaN or ZnO, w‑BN is distinguished by its theoretical hardness exceeding that of diamond and its remarkable thermal and chemical stability.

2. Crystal Structure & Key Properties

Wurtzite boron nitride adopts a hexagonal crystal system with space group P6₃mc. It features tetrahedrally coordinated boron and nitrogen atoms arranged in a 3D network similar to the wurtzite structure of ZnS or GaN. Each B–N bond is covalent, contributing to the material's exceptional mechanical rigidity.

Compared with other BN polymorphs:

-

h‑BN: Layered structure like graphite; weak interlayer forces, good lubricity.

-

c‑BN: Cubic zinc-blende structure; second-hardest known material after diamond.

-

w‑BN: Tetrahedral coordination but arranged in wurtzite lattice; predicted to have higher indentation strength than both c‑BN and diamond due to its unique deformation mechanisms under stress.

Lattice parameters of w‑BN:

-

a ≈ 2.55 Å

-

c ≈ 4.23 Å

3. Structure–Performance Correlation

3.1 Hardness vs. Toughness

-

The strong sp^3‑type B–N bonding in wurtzite BN drives hardness, but its non-cubic symmetry boosts toughness in certain orientations.

3.2 Thermal & Oxidative Behavior

-

Orientation-dependent thermal expansion can affect film integrity, critical in high-heat coatings or microelectronics substrates.

3.3 Electrical Properties

-

Wide bandgap limits electron mobility, but film thickness and defect control can tailor dielectric properties for microelectronic use.

4. Synthesis Approaches

Producing w‑BN is non-trivial, requiring tightly controlled conditions and specialized equipment:

4.1 High-Pressure, High-Temperature (HPHT) Conversion

Wurtzite BN is typically synthesized by converting h‑BN or c‑BN under extreme pressure (7–20 GPa) and high temperature (1700–2200 °C). Transition metals like Ni or Co are often used as catalysts. The process yields small crystallites embedded in the parent phase, limiting scalability.

4.2 Shock Compression

Shockwave compression of h‑BN using explosive or laser-driven techniques can induce transient transformation to w‑BN. This rapid, non-equilibrium process produces nanoscale regions of w‑BN but poses reproducibility challenges.

4.3 Pulsed Laser Deposition (PLD)

PLD has been explored to grow thin films of BN with wurtzite-like features on substrates such as sapphire or SiC. Film crystallinity and phase purity remain issues, but this method offers control over deposition parameters.

4.4 Ion Implantation and Annealing

Implanting nitrogen or boron ions into layered substrates followed by annealing at high pressure may stabilize the wurtzite phase. Research is ongoing to optimize energy doses and annealing protocols.

5. Application Prospects & Case Studies

5.1 Superhard Coatings & Abrasives

Tool coatings for micro-machining, e.g., silicon wafer dicing blades. Early lab tests show improved wear resistance over c‑BN under aggressive loads.

5.2 High-Temp Protective Layers

Deposited via PVD onto turbine blades, combustion chamber linings, or reactor parts to enhance lifetime in oxidizing atmospheres.

5.3 Microelectronic & Power Substrates

Potential as insulating, heat-spreading base layers for wide-bandgap semiconductors like GaN or SiC. Early prototypes show improved thermal cycling durability.

5.4 Research in Optical Windows & Sensors

UV-transparent properties (~220 nm cutoff) and hardness suggest use in aerospace-grade windows and slide-in sensors for hostile environments.

6. Summary

Wurtzite boron nitride represents a unique and intriguing member of the BN family. While not yet available in commercial quantities, its outstanding theoretical hardness and chemical resilience make it a compelling target for advanced applications where traditional ceramics fall short. As synthesis methods improve, w‑BN may evolve from a scientific curiosity into a high-performance material of strategic importance.

At Stanford Advanced Materials, we supply a range of boron nitride products, including wurtzite BN powders and other BN-based materials for demanding thermal, dielectric, and wear-resistant applications. Whether you're sourcing for high-temperature environments or exploring advanced ceramic options, our team is here to support your material selection and procurement needs.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento