Tantalum Mining: What, Where, and How

Tantalum is a scarce, resilient metal that has a high melting point, is resistant to corrosion, and is a good conductor—qualities that make it vital for use in capacitors, semiconductors, and aerospace alloys. But where does it originate, and how is it acquired? This piece provides answers to four fundamental questions: What is tantalum? Where is it mined? How is it extracted and processed? And what are the environmental and ethical consequences of tantalum mining?

What Is Tantalum?

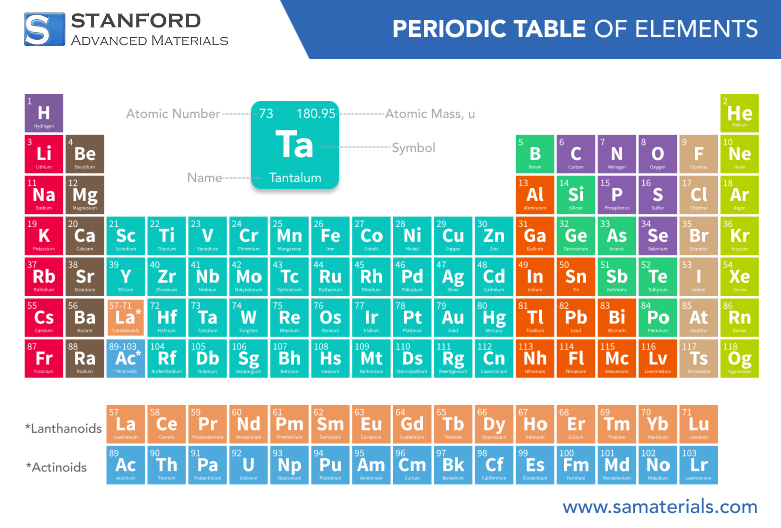

Tantalum (Ta, atomic number 73) is a transition metal with high resistance to heat and chemical corrosion and a high melting point (3,017°C). Tantalum is employed as powder or wire, and some 60–70% of global production is consumed in tantalum capacitors—critical components in smartphones, laptops, and automotive electronics.

Tantalum is chemically similar to niobium and is always present with it in nature. While both are used in high-performance alloys and electronics, tantalum is more valuable and rarer.

How Many Types of Tantalum Ores Are There?

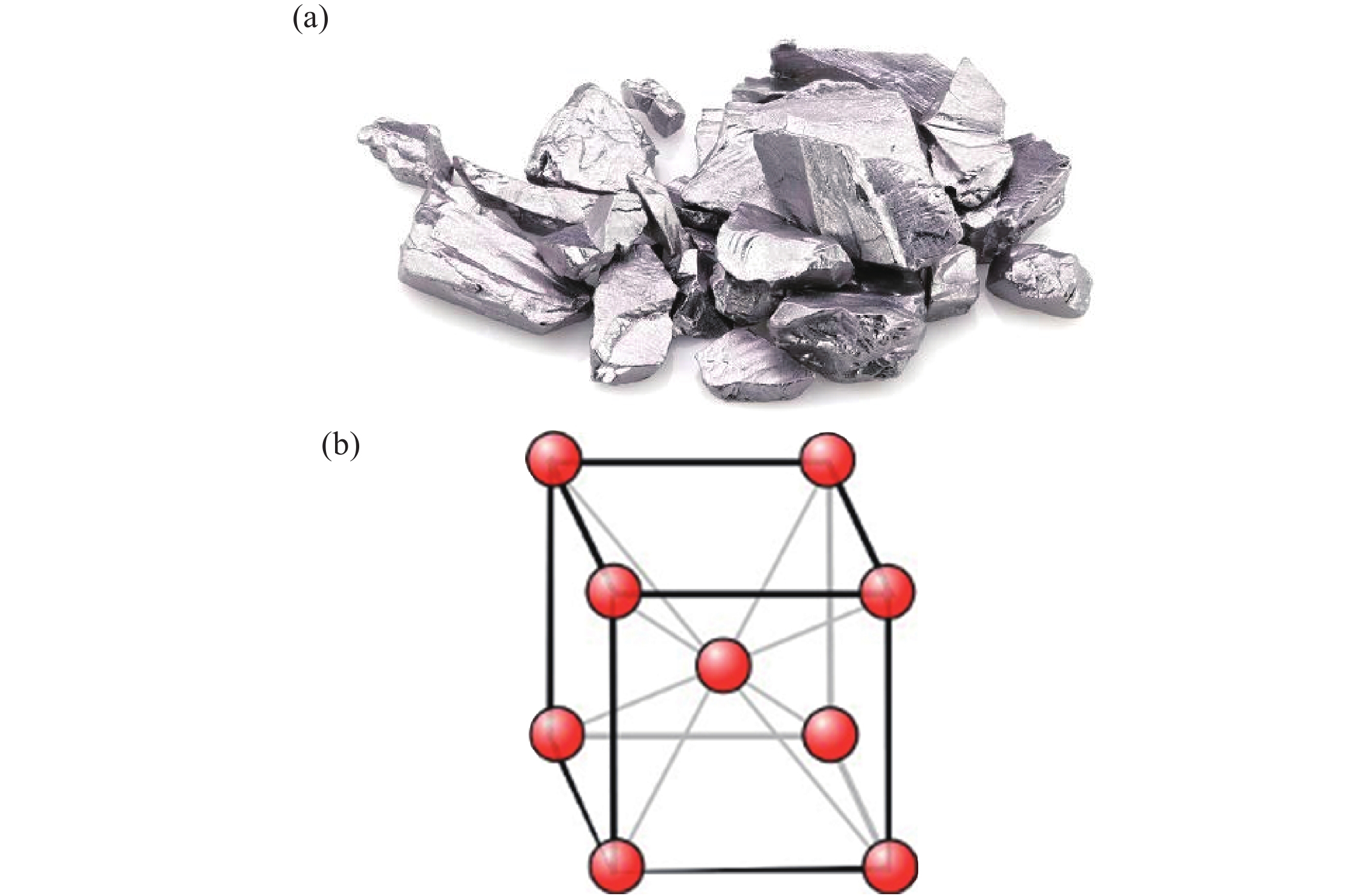

Tantalum does not occur in pure metallic form in nature. Instead, it is present in a variety of minerals, most notably:

- Coltan – a shortened form of columbite–tantalite, the most economically valuable ore.

- Tantalite – tantalum-prevailing end member of the coltan group.

- Microlite, Wodginite, and others – less prevalent sources mined in localized regions.

[1]

[1]

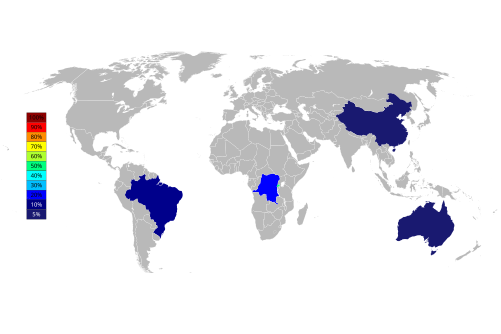

Where Is Tantalum Mined?

Global Tantalum production is concentrated in several countries. Historically and according to industry trends, Rwanda, Democratic Republic of the Congo (DRC), Brazil, Nigeria, and Australia have typically led global supply, whether through artisanal production, industrial production, or as a by-product of tin production.

1. Rwanda – ~950 Metric Tons

Rwanda has been the world's foremost tantalum producer in recent years, with around 50% of the world's supply. Most of its production comes from artisanal and small-scale mines, yet the nation has attained high traceability and responsible sourcing under programs like the International Tin Supply Chain Initiative (ITSCI). Rwanda exported about 950 metric tons of tantalum concentrate in the year 2023, still reigning supreme in the international market.

2. Democratic Republic of the Congo (DRC) – ~400 Metric Tons

The DRC remains a major source of coltan, the mineral from which tantalum is produced. In 2023, the country produced an estimated 400 metric tons of tantalum, primarily from artisanal mining operations in the eastern provinces. Due to its resource wealth, DRC's mining sector remains plagued by conflict financing concerns, smuggling, and labor abuses. Certified supply chains have, nonetheless, begun to emerge, offering tantalum from certified conflict-free zones.

3. Brazil – ~300 Metric Tons

Brazil is a long-standing producer of tantalum, with most production coming from industrial operations in Minas Gerais and Paraíba. In 2023, Brazil produced an estimated 300 metric tons of tantalum concentrate. Tantalum from Brazil is frequently mined as a by-product of tin and niobium operations, with the advantage of the country's established mineral processing infrastructure.

4. Nigeria – ~250 Metric Tons

Nigeria is not typically thought of but is actually one of the top tantalum producers, averaging 250 metric tons in recent years. Nigeria boasts extensive pegmatite belts, particularly spanning states like Kogi and Nasarawa. Production is mostly artisanal and informal, but the government is in the process of formalizing and regularizing the sector, with scope to increase production and transparency.

5. Australia – ~100–150 Metric Tons

Australia was once the world's largest producer of tantalum, with significant operations at Greenbushes and Wodgina. While production plummeted in the late 2010s due to market oversupply and project closures, production restarted in recent years. Production in 2023 was estimated at between 100 and 150 metric tons, with scope for more as global demand for ethically sourced tantalum grows. Australia boasts the benefit of stable governance, high-grade ore, and advanced mining infrastructure.

[2]

[2]

How Is Tantalum Mined and Refined?

--Artisanal and Small-Scale Mining (ASM)

A significant portion of tantalum in Central Africa is extracted through artisanal mining. Miners utilize physical labor and simple equipment to excavate coltan-containing ore from riverbeds or the ground. ASM provides livelihoods for thousands of people but is often informal, with limited safety measures and environmental controls.

--Industrial Mining

In Australia and Brazil, tantalum is mined through large-scale underground or open-pit mining. These mines utilize advanced machinery, drilling, and controlled blasting for effective ore removal. Industrial-level mining offers higher purity and consistency of product, with more control over working and environmental conditions.

After mining, tantalum ores are processed through a series of steps:

- Crushing and grinding to reduce ore size.

- Gravity separation to concentrate tantalum-bearing minerals.

- Flotation or magnetic methods to remove impurities.

- Chemical processing (e.g., HF leaching) to separate tantalum from niobium.

- Refining to produce tantalum powder, oxide, or ingots that are used in electronics, superalloys, and medical implants.

What Are the Impacts of Tantalum Mining?

--Conflict Minerals

The majority of the world's coltan is excavated in regions plagued by armed conflict, particularly in the DRC. Revenue from tantalum mining has historically funded violence. In response, the Dodd-Frank Act (Section 1502) requires U.S. companies to report sourcing of tantalum (and other conflict minerals).

--Human Rights and Labor

Artisanal miners typically work in unsafe conditions, with reports of child labor, exploitation, and poor equipment.

--Environmental Concerns

Ore mining and processing can lead to deforestation, water pollution, and dangerous tailings disposal if not properly managed.

--Ethical Sourcing Programs

Organizations like the OECD and initiatives like ITSCI (International Tin Supply Chain Initiative) and RMI (Responsible Minerals Initiative) promote responsible sourcing and transparency through traceability audits and certification schemes.

Conclusion

Tantalum is a small but vital ingredient enabling modern electronics and hi-tech manufacturing. Yet, tantalum mining is beset by ethical, environmental, and geopolitical risks. As demand rises, efforts to source tantalum responsibly—from large-scale industrial operations, certified artisanal mines, and recycling—will be central to building a secure and sustainable future. For more tantalum products and tech support, please check Stanford Advanced Materials (SAM).

Reference:

[1] Zhenyu YANG, Jiangqi ZHU, Xingchen YAN. 3D Printing of Tantalum Medical Metal Materials[J]. Metal World, 2023(6): 16-23. DOI: 10.3969/j.issn.1000-6826.2023.10.0885

[2] Tantalum. (2025, June 15). In Wikipedia. https://en.wikipedia.org/wiki/Tantalum

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento