Stanford Advanced Materials Provided CBN Solutions for Aerospace Tooling

Introduction

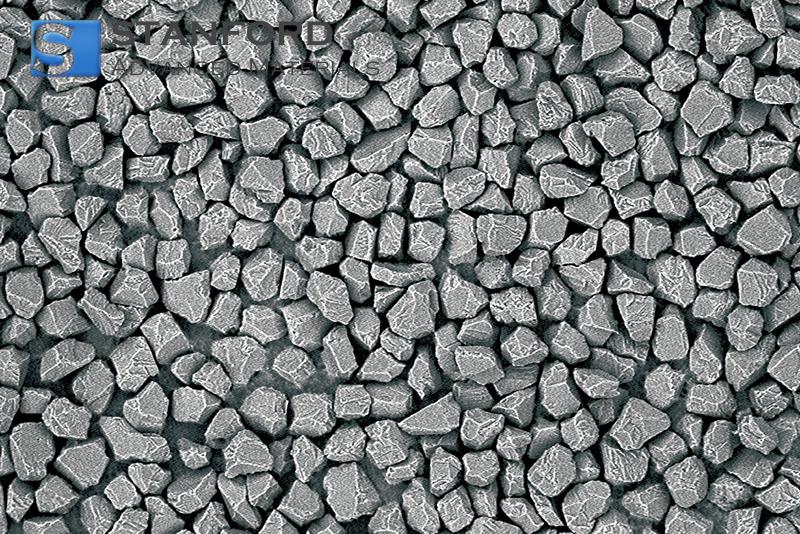

Stanford Advanced Materials (SAM) is delighted to share a success story in the usage of Cubic Boron Nitride (cBN), a superhard material that is well known for its outstanding thermal stability and chemical inertness. SAM's cBN solutions helped a prominent aerospace manufacturer to resolve serious tool wear issues in high-precision machining of hardened ferrous alloys.

SAM Senior Ceramics Engineer Ms. Lisa Ross states:

"Cubic Boron Nitride gives engineers an edge—literally and figuratively—where diamond falls short. This is exactly the kind of high-performance, application-specific solution SAM is well-suited to provide."

Case Study of Cubic Boron Nitride

--The Challenge: Tool Wear in Aerospace Machining

A major producer of aerospace parts introduced SAM to a significant issue. Their production lines, which involved precision machining of hardened steel and nickel-based superalloys for jet engine parts, were experiencing severe tool degradation. Even coated carbide tools were not holding up and diamond tools were chemically reacting with the ferrous metals.

The key pain points were:

- Frequent tool changes disrupting production

- Edge wear and loss of part tolerance

- Excessive heat during high-speed cutting

- Increased costs because of short tool life

The customer required a product with high temperature resistance, chemical wear resistance, and the ability to stay sharp even under extreme machining conditions.

--SAM's Solution: Cubic Boron Nitride Inserts and Powders

Stanford Advanced Materials, after reviewing the application thoroughly, recommended its range of Cubic Boron Nitride (cBN) products. They provide high-purity cBN powders specially designed for sintered cutting tool manufacture and pre-made cBN cutting inserts specially designed for machining ferrous alloys.

Why utilize cubic boron nitride (cBN)? Firstly, cBN is only second to diamond in terms of hardness and therefore provides very good resistance to wear. In addition, it has exceptional thermal stability with continuous performance at temperatures up to 1350 °C in air. It is chemically inert, which makes it non-reactive to iron or steel, and resists undesirable reactions during machining. Finally, cBN has better edge retention, especially during dry or high-speed cutting conditions, which translates to longer tool life and stability of performance. Together, these advantages make cBN a material of choice for extreme industrial applications.

SAM also provided technical advisory on tooling selection, cutting conditions, and CNC operation integration. The goal was to optimize tool life without sacrificing dimensional precision and repeatability in large-series production.

--Implementation and the Results

The aerospace customer incorporated SAM's cBN tools in their turbine blade and structural steel bracket finishing applications. The performance results showed clear, measurable benefits:

- Tool life was 4.5× longer, reducing tool change frequency and downtime

- 18% reduction in machining cycle times due to higher cutting speeds

- Improved surface finish and dimensional tolerance to meet aerospace quality standards

- 32% reduction in overall tooling cost over six months of testing

These benefits led to company-wide implementation of cBN tooling on the company's high-alloy machining lines. The improved performance allowed engineers to meet shorter delivery schedules with reduced waste and rework.

What is Cubic Boron Nitride?

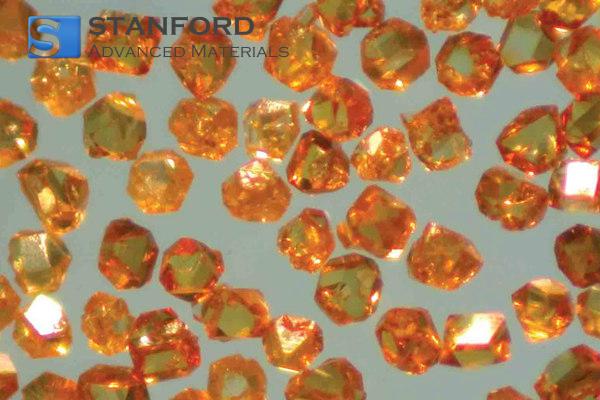

Cubic Boron Nitride (cBN) is a superhard synthetic material with a cubic crystal structure, similar to diamond. It is widely used in high-precision machining where the extreme hardness and heat resistance are required. cBN has no chemical reaction with ferrous metals like diamond and hence is ideal for machining hardened steels, cast irons, and superalloys.

The following are the key features of cBN:

|

Feature |

Value |

|

Hardness |

~4500 kg/mm² (Vickers) |

|

Thermal Stability |

Up to 1350 °C in air |

|

Electrical Resistivity |

>10⁶ Ω·cm |

|

Chemical Resistance |

Inert to iron, steel, and nickel alloys |

|

Machinability |

Suitable for precision lapping and grinding |

SAM's cBN products are engineered to meet the requirements of aerospace, automotive, and advanced manufacturing applications and are offered in powder, sintered inserts, or composite forms.

Further reading: Why is Cubic Boron Nitride Called a Superhard Material?

Applications of Cubic Boron Nitride

Cubic boron nitride (cBN) finds extensive uses.

- It is extensively used in machining tool steels, hardened steel, and high-strength alloys due to its high wear resistance and hardness.

- In addition, cBN is used in precision grinding tools for aerospace and automotive parts, where accuracy and durability are of utmost importance.

- It is also used as a wear-resistant coating on dies and forming tools to enhance their life.

- Additionally, cBN is utilized in heat-resistant components that are designed for high-speed cutting applications.

- Because of its unmatched durability and superior thermal stability, cBN is generally the preferred material when diamond and carbide tools are no longer practical.

Conclusion

Cubic boron nitride (cBN) is of extremely high value as a cutting tool material because it possesses a unique blend of high hardness and thermal and chemical stability. Stanford Advanced Materials (SAM) is a leading global provider of engineered ceramics and hard materials. To learn more about SAM's cBN products or receive a customized quote, visit homepage.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento