Stanford Advanced Materials Advances Precision Machining with WBN

Introduction

Stanford Advanced Materials (SAM) is pleased to share a success story in the application of Wurtzite Boron Nitride (WBN). This superhard material is prized for its extreme hardness, thermal stability, and shock resistance. SAM’s WBN-based tool solutions helped a precision machining company overcome persistent tool degradation issues during the intermittent turning of hardened steels.

As Lisa Ross, Senior Ceramics Engineer at SAM, explains:

“Wurtzite BN composites—especially when reinforced with fine diamond particles—offer a unique combination of toughness and heat resistance that surpasses conventional superhard materials. It’s a game-changer for advanced machining challenges.”

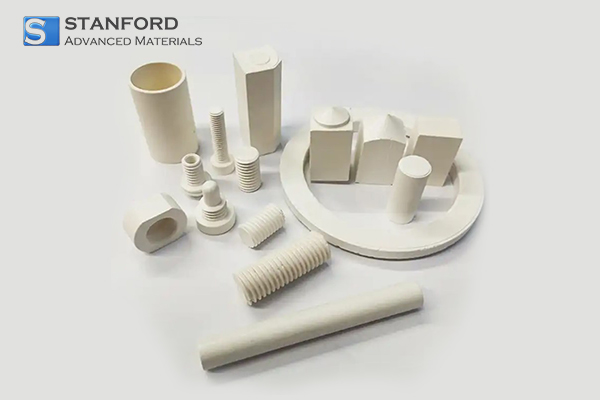

Fig. 1 Customized Boron Nitride Parts

Case Study of Wurtzite Boron Nitride

—The Challenge: Tool Wear under Shock-Load Machining

A precision machining firm specializing in hardened steel components encountered serious challenges during high-speed, intermittent turning operations. Their existing tools suffered from rapid edge chipping and thermal wear, particularly in applications involving 100Cr6 bearing steel with a hardness of 61–63 HRC. The main issues included:

- Premature tool failure due to edge fracture during interrupted cutting.

- Excessive heat buildup in the cutting zone.

- Inconsistent dimensional control caused by uneven wear.

- Increased production downtime due to frequent tool changes.

The company needed a tool material that could simultaneously resist thermal degradation and survive the mechanical shocks associated with interrupted cuts.

Further reading: HBN, CBN, and WBN: A Comparative Analysis of Boron Nitride Polymorphs

—SAM’s Solution: WBN-Diamond Composite Inserts

After evaluating the client’s application in detail, SAM recommended a specialized cutting insert made from polycrystalline Wurtzite Boron Nitride (WBN) reinforced with nano-diamond particles. This material was selected for its ability to combine the thermal conductivity of diamond with the impact toughness of WBN.

The key advantages of the WBN-diamond composite included significantly improved thermal management, as the diamond phase helped dissipate heat away from the cutting edge, reducing localized temperature buildup. The material also exhibited exceptional hardness, with reinforced polycrystalline WBN reaching values as high as 54 GPa. Additionally, it demonstrated excellent resistance to abrasive wear and edge micro-chipping, even under aggressive and high-impact cutting conditions.

SAM provided technical support on cutting parameters, recommended sintering temperatures, and optimized diamond content for the inserts, ensuring reliable integration into the client’s CNC operations.

--Implementation and Results

The WBN-diamond tools were tested in finishing operations involving hardened bearing steel. The results were significant:

- Tool life increased by over 300%, withstanding multiple cycles of interrupted cutting without edge failure.

- Machining temperature at the cutting interface was reduced by approximately 20%, extending insert performance.

- Surface finish improved from Ra 0.6 µm to Ra 0.3 µm, meeting the client’s aerospace-grade tolerances.

- Total tooling cost was reduced by 27% over a 3-month period due to fewer replacements and lower scrap rates.

What Is Wurtzite Boron Nitride?

Wurtzite Boron Nitride is a high-pressure, high-temperature polymorph of boron nitride with a hexagonal crystal structure that transforms into a wurtzite form under extreme conditions. It is one of the hardest known synthetic materials, with reported Vickers hardness values ranging from 24 GPa to over 50 GPa in composite form.

Key properties of WBN include:

|

Property |

Value |

|

Hardness |

~24–54 GPa (depending on phase and composition) |

|

Thermal Stability |

Up to 1400 °C in inert atmospheres |

|

Chemical Resistance |

Inert to iron, steel, and nickel alloys |

|

Fracture Toughness |

Higher than diamond or cBN |

|

Electrical Resistivity |

>10⁶ Ω·cm |

WBN is typically produced as powders or sintered inserts and is increasingly used in high-precision, high-impact machining operations where traditional tool materials fail.

Further reading: Wurtzite Boron Nitride (w‑BN): Structure, Properties, and Applications

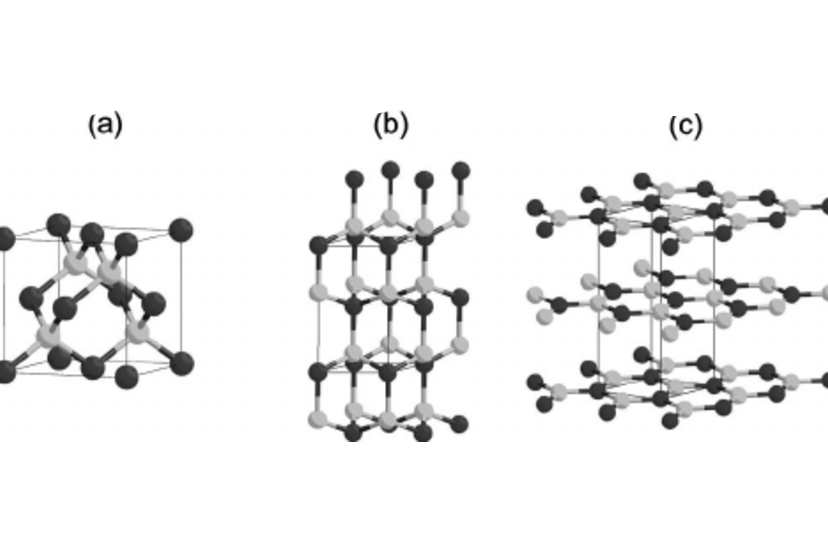

Fig. 2 Crystal structure of BN in ͑ a ͒ the cubic zinc-blende phase, ͑ b ͒ the wurtzite phase, and ͑ c ͒ the hexagonal phase.[1]

WBN vs Diamond

While both Wurtzite Boron Nitride and diamond are considered superhard materials, they differ significantly in their industrial utility. Diamond, though the hardest known material, reacts chemically with ferrous metals at elevated temperatures, limiting its use in machining steels and iron-based alloys. It is also brittle and more prone to edge chipping under impact or interrupted cutting.

WBN, by contrast, maintains excellent chemical stability with ferrous materials and displays greater fracture toughness. This makes WBN especially suitable for demanding applications involving thermal cycling or intermittent contact. When combined with diamond in composite structures, WBN tools gain the thermal benefits of diamond while retaining their mechanical reliability—offering a balanced, high-performance solution

Conclusion

Stanford Advanced Materials helped a precision machining client successfully overcome tool degradation challenges with advanced Wurtzite Boron Nitride. By delivering engineered WBN-diamond composites, along with application-specific guidance, SAM enabled longer tool life, higher process reliability, and improved surface quality.

To learn more about WBN tools or request a customized solution, visit www.samaterials.com.

Reference:

[1] Janotti, Anderson & Wei, Su-Huai & Singh, Dr. (2001). First-principles study of the stability of BN and C. Physical Review B - Condensed Matter and Materials Physics. 64. 1741071-1741075.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento